🪶 Why Aluminum Hinges Are Redefining Modern Door Design

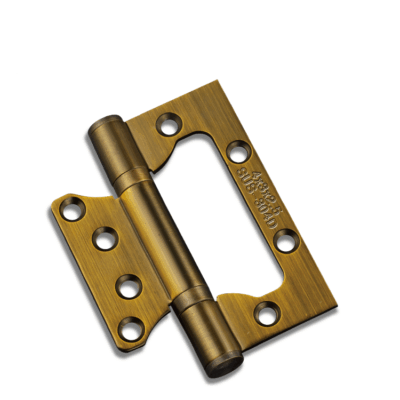

As industries push for lighter, more efficient structures—from office partitions to caravan doors—aluminum hinges have become the preferred solution for designers and manufacturers.

Unlike steel, aluminum provides an optimal balance of weight, corrosion resistance, and cost efficiency. It is easy to machine, recyclable, and compatible with a wide range of finishes. For scalable production, buyers often collaborate with reliable Aluminum Hinges Manufacturers or integrated Hinge Manufacturers factory networks to guarantee consistent anodizing and mechanical strength.

⚙️ Material Advantages: Lightweight Yet Strong

Aluminum’s density is about one-third that of steel, yet through proper alloy selection (typically 6061 or 6063), it achieves excellent strength-to-weight ratios.

Key engineering benefits include:

-

Reduced mass: Cuts total door weight by up to 40%.

-

Corrosion resistance: Naturally forms an oxide layer that prevents rust.

-

Machinability: Allows custom hinge profiles and tight tolerances.

-

Aesthetic flexibility: Can be polished, brushed, or anodized in multiple tones.

These properties make aluminum hinges ideal for furniture doors, electrical enclosures, cleanroom equipment, and mobile vehicle systems where every gram counts.

🧪 Anodizing: The Secret to Durability and Color

Raw aluminum oxidizes naturally, but anodizing enhances this protection. The process thickens the oxide layer (5–25 µm), improving scratch and corrosion resistance while allowing color customization.

Popular anodized finishes include:

-

Silver Natural: Matches most aluminum frames and doors.

-

Black or Bronze: Modern look for architectural interiors.

-

Champagne or Gold: Decorative and premium tone for designer furniture.

During sourcing, always verify the anodizing thickness, hardness, and adhesion test results. A dependable hinge factory ensures consistency between batches through in-house anodizing lines and QC certificates.

🧰 Structural Design for Lightweight Applications

Although aluminum is lighter, hinge geometry must still handle torque and shear forces properly. Design engineers often apply reinforcement through:

-

Thicker leaf edges (≥3 mm) to increase rigidity.

-

Precision-pinned barrels for smoother rotation.

-

Brass or stainless bushings to reduce friction.

-

Symmetrical knuckles for balanced load transfer.

When working with OEM hinge factories, provide torque data and door dimensions early. This allows optimization of pin diameter and knuckle pitch before mold cutting—saving tooling time and reducing long-term fatigue failures.

💧 Corrosion Resistance and Environmental Adaptability

Aluminum naturally resists oxidation, but in aggressive environments such as coastal zones or cleanrooms, additional coatings may be necessary.

Recommended treatments include:

-

Hard anodizing (≥20 µm) for industrial applications.

-

Powder coating for color stability and UV resistance.

-

Electrophoretic coating for indoor decorative parts.

Laboratory tests should verify no pitting or discoloration after 500 hours of salt-spray. Partnering with a certified Hinge Manufacturers factory ensures these protective standards are met before export.

🧱 Cost and Sustainability Considerations

From a procurement standpoint, aluminum hinges deliver strong ROI due to:

-

Lower raw material cost per weight unit.

-

Reduced shipping and installation labor.

-

Recyclability without quality loss—supporting ESG compliance.

Compared to stainless steel, aluminum’s tooling and machining costs are typically 20–30% lower, making it a preferred choice for mass production of modular systems and OEM furniture.

For companies prioritizing sustainability, working with hinge factories that utilize recycled aluminum billets helps reduce carbon footprint without compromising strength.

🏭 OEM Customization and Branding Options

Aluminum’s machinability allows nearly unlimited customization for OEM projects:

-

Unique profiles to fit extrusion systems.

-

Embedded logo engraving or laser marking.

-

Integrated damping or self-closing features.

-

Multiple anodized color options to match brand palettes.

Reliable Aluminum Hinges Manufacturers can produce prototypes within weeks, enabling rapid sampling before final mass production at global Hinge Manufacturers factory partners.

🔍 Conclusion

Aluminum hinges combine efficiency, aesthetics, and strength in a way that modern design demands. Their lightweight nature, corrosion resistance, and flexible anodizing options make them the perfect choice for architects, cabinetmakers, and industrial designers alike.

For dependable supply, certified testing, and consistent color matching, collaborate with trusted Aluminum Hinges Manufacturers and global Hinge Manufacturers factory networks that understand the engineering and visual precision your brand requires.