🔥 Why Fire-Rated Hinges Matter More Than You Think

Fire-rated doors save lives—but they can only perform as designed if the hinges holding them remain functional during extreme heat. A door with incorrect or uncertified hinges can fail in minutes, allowing flames and smoke to spread rapidly.

In today’s construction standards, the hinge is not a small accessory—it’s a critical safety component. Procurement teams must ensure all hinges used on fire-rated assemblies comply with internationally recognized standards and carry valid certification.

Working with qualified Door Hinges Manufacturers or authorized Hinge Manufacturers suppliers guarantees both traceability and liability coverage.

🧱 Certification Standards You Must Know

Fire-rated hinges are certified under several global standards that evaluate performance under temperature, load, and duration:

-

EN 1634-1 (Europe): Fire resistance test for door assemblies, including hinges.

-

BS 476 Part 22 (UK): Commonly used in architectural hardware tests.

-

UL 10C (USA): Fire tests for door assemblies, especially steel doors.

-

CE Marking: Indicates conformity with EU Construction Products Regulation (CPR).

Each standard defines test duration—typically 30, 60, 90, or 120 minutes—and specifies the hinge configuration used. When purchasing hinges in bulk, always verify that test certificates match the door configuration you intend to use (single leaf, double leaf, or glazed).

🔩 Intumescent Technology Explained

Fire-rated hinges often integrate intumescent materials—heat-activated compounds that expand dramatically when exposed to high temperatures.

Here’s how it works:

-

At around 180–200°C, the intumescent layer expands up to 20 times its original thickness.

-

This expansion seals gaps around hinge knuckles and screws, preventing hot gases from escaping.

-

It also helps stabilize the hinge by filling voids created by heat deformation.

Many reputable hinge suppliers now offer hinges with pre-fitted intumescent pads, simplifying on-site compliance and reducing installation time. Always confirm pad material type (e.g., graphite-based or phosphate-based) and expansion ratio in your technical datasheet.

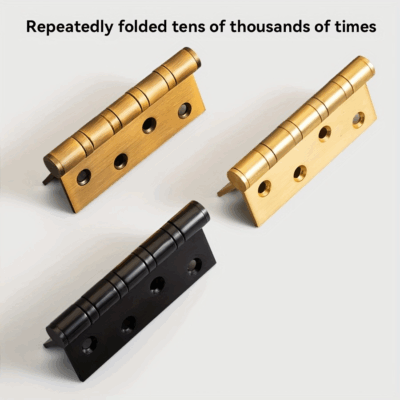

⚙️ Material and Structural Considerations

The hinge’s material determines its ability to survive high temperatures without failure.

-

Steel Hinges (Mild or Stainless): Most common due to their melting point and mechanical stability.

-

Brass Hinges: Generally avoided for high-rating applications because of lower heat tolerance.

-

Stainless Steel (304 or 316): Preferred for durability, oxidation resistance, and structural retention.

Key design features to look for:

-

Minimum 3 hinges per leaf (required by EN 1935).

-

Fixed pins or non-removable knuckles for security.

-

High-tensile screws to maintain holding strength under heat stress.

Fire-rated hinges should always be installed with fire-rated screws supplied in the same certification set—substituting fasteners voids certification.

🧪 Testing and Compliance Documentation

Before procurement, verify the following:

-

Third-party test report (from UL, Intertek, Warringtonfire, etc.).

-

Manufacturer’s Declaration of Performance (DoP) for CE-marked products.

-

Batch number and expiry date on packaging.

-

Intumescent pad test certificate (when applicable).

For project-level compliance, hinge suppliers should issue a Certificate of Conformity referencing both hinge and door model numbers.

This documentation is essential during building inspections and liability audits.

🧰 Installation and Maintenance

Fire-rated hinges only function as tested if installed correctly.

Practical tips include:

-

Do not drill or modify hinge leaves.

-

Maintain correct screw torque to avoid distortion.

-

Replace damaged intumescent pads immediately.

-

Reinspect hinges annually for wear or corrosion.

In humid environments or high-traffic doors, consider 316 stainless steel fire-rated hinges to prevent corrosion and maintain integrity over time.

💼 Liability and Insurance Implications

Using uncertified hinges in fire doors exposes contractors to legal and financial risk.

In case of fire, investigators trace door hardware back to suppliers—if hinges are found non-compliant, insurance claims may be denied.

Partnering with a certified Door Hinges Manufacturers or reputable Hinge Manufacturers supplier ensures:

-

Valid third-party certification

-

Material traceability down to production batch

-

Liability coverage supported by test data

This professional documentation safeguards both safety compliance and brand reputation.

🔍 Conclusion

Fire-rated door hinges aren’t just hardware—they are life-safety devices.

Every screw, pad, and pin must perform under fire conditions exactly as tested.

Procurement teams should always prioritize certified hinge suppliers who provide transparent testing records and ensure installation kits include all required components.

For guaranteed compliance and peace of mind, choose proven Door Hinges Manufacturers and internationally trusted Hinge Manufacturers networks—because in fire safety, reliability is non-negotiable.