🏗 The Hidden Complexity of Multi-Site Hinge Procurement

For construction companies, furniture manufacturers, and infrastructure developers, hinges might appear like a small detail—but in large-scale rollouts, they can become a serious logistical challenge.

Each project may require dozens of hinge models with unique specifications, finishes, and certifications. Without a unified procurement strategy, SKU proliferation leads to inconsistent installation quality and inflated inventory costs.

That’s why experienced buyers rely on structured sourcing networks such as Hinge Manufacturers and verified Hinge Wholesale suppliers to maintain quality, traceability, and cost stability across sites.

📦 Step 1: Define Standardized SKU Architecture

The foundation of scalable procurement is SKU standardization. Instead of allowing every site or contractor to choose their own hinge models, procurement should define a limited set of approved SKUs that cover 90% of project needs.

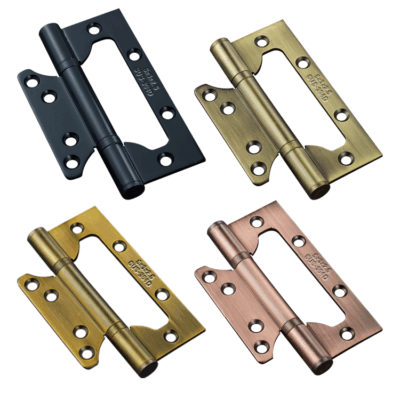

This means grouping hinges by:

-

Function (door, cabinet, continuous, shower, etc.)

-

Material (steel, brass, aluminum, stainless steel)

-

Finish (satin, polished, black, PVD, etc.)

-

Rating (fire-rated, soft-close, outdoor-grade)

A unified SKU structure ensures every order aligns with the same performance and compliance standards, regardless of project location.

📑 Step 2: Evaluate and Prequalify Suppliers

Before any mass rollout, conduct a supplier audit to assess production capacity, QC systems, and delivery reliability. Key criteria include:

-

ISO 9001 and EN 1935 certifications

-

Documented test results (salt-spray, fatigue, cycle life)

-

On-time delivery rate and minimum stockholding capacity

-

ERP system integration for order tracking

Selecting a hinge supplier is about partnership, not just price. Companies with global fulfillment networks—such as integrated Hinge Manufacturers groups—offer both technical assurance and scalable production under unified quality control.

🚚 Step 3: Logistics Coordination Across Sites

Rolling out hinges across multiple builds requires a precise balance between centralized planning and local flexibility.

Best practice is to:

-

Maintain a central master inventory at regional distribution centers.

-

Use JIT (Just-in-Time) replenishment to reduce site storage load.

-

Label all cartons with project code, SKU, and batch number for traceability.

-

Standardize packaging dimensions to simplify palletization.

Professional hinge suppliers can even integrate with your ERP or warehouse management system (WMS) to automatically update shipment and usage data.

🧰 Step 4: Traceability and Quality Control

One of the biggest risks in multi-site procurement is quality drift—different batches from different plants performing inconsistently.

To prevent this:

-

Require each hinge to carry a batch or QR code.

-

Request COC (Certificate of Conformity) for every delivery.

-

Use third-party inspections for random sampling on-site.

-

Track performance feedback from each site for continuous improvement.

Top-tier suppliers provide cloud-based QC dashboards that display inspection photos, torque readings, and salt-spray data per batch—allowing buyers to monitor global quality from one platform.

💰 Step 5: Cost Optimization Through Volume Bundling

Consolidating purchases across projects unlocks economies of scale. By negotiating annual volume contracts with a single hinge supplier, you can achieve:

-

Up to 15–25% cost reduction via aggregated order forecasts

-

Simplified invoicing and payment cycles

-

Faster prototype approval for new product variants

Hinge Wholesale networks specialize in this model, offering flexible MOQs and stable pricing even in volatile metal markets.

🧩 Step 6: Communication Between Procurement, Engineering, and Site Teams

No procurement plan works in isolation. Communication between departments ensures that engineering changes, sample feedback, or site issues reach suppliers quickly.

Practical steps:

-

Create a shared hinge specification document.

-

Set up periodic joint reviews with suppliers.

-

Maintain an issue-tracking system to record on-site deviations.

This collaborative model avoids version mismatches (e.g., wrong leaf thickness or finish) and ensures continuous improvement over the project lifecycle.

🌍 Step 7: Sustainability and Documentation

Modern tenders increasingly require ESG reporting—tracking recycled content, origin certificates, and carbon footprints.

Professional hinge suppliers already support this with:

-

Recycled alloy statements (e.g., 60% recycled brass or aluminum).

-

REACH & RoHS compliance documentation.

-

Lifecycle carbon data per SKU.

Integrating these reports into your procurement system strengthens brand transparency and aligns with sustainable development goals.

🔍 Conclusion

Scaling hinge procurement across multiple construction sites isn’t just about managing components—it’s about orchestrating consistency, reliability, and accountability.

By establishing standardized SKUs, partnering with audited Hinge Manufacturers, and leveraging Hinge Wholesale networks, procurement teams can secure both technical precision and logistical efficiency.

A well-built hinge supply chain doesn’t just hold doors—it holds together the credibility of your entire project ecosystem.